Progress update: trailer, systems design, indoor build space & materials quotes

The past couple of weeks have been very busy, though I haven't started building yet. Here's what's happened in Tiny Project land:

Trailer

3' extension to back of trailer

I visited Mac-Lander in Milton, IA to see my trailer as it was being constructed and to discuss a few options to complete it with my desired modifications. We decided on the addition of 3 feet of steel frame off the rear of the trailer so that the lights can be moved to the back and will not be covered by a cantilevered porch overhang. They will also be adding some custom brackets (as discussed here) to help secure the subfloor to the trailer, by bolting it on from both the sides and bottom. 5 brackets (with vertical tabs for bolting through the side) will be added in front of the wheels, and 3 behind, on each side of the trailer.

The trailer is a beast! It's very sturdy, and will be a perfect foundation for my tiny house. I wish I had thought to take a picture while I was there so I could show the unfinished welded frame. It was very fun to witness some of the process ... and all the work it takes to make one of these from scratch.

My trailer should be done sometime this week -- then I'll really have to get moving on getting all of my materials so I can start building right away!

Systems Design

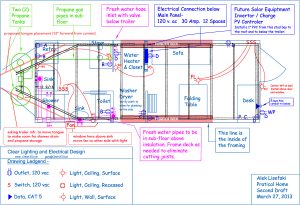

Systems diagram in progress - with trailer frame overay

I'm currently working with Gary Bute of Clear Lighting & Electrical Design to design my electrical, plumbing and propane systems. Gary has very generously donated his time to consult on these systems and draw up some accurate diagrams for where and how plumbing and wiring will be installed throughout the house. He has already influenced my plans in many great ways, with invaluable insight into the construction process, lighting issues, and optimal placement of plumbing or wiring, including moving much of it into the sub-floor rather than the walls. Thank you Gary!

Indoor Construction Space

So far I've met with one local company in attempts to barter for use of an indoor warehouse space. I was originally planning to build the entire thing outdoors, but now I'm realizing how nice it would be to have a level, dry floor to work on (until I get the shell finished and can move it home for all the interior work). Just to have space on a cement floor to assemble the wall framing, will, in itself, save a lot of time and headache. Stay tuned to see if this works out!

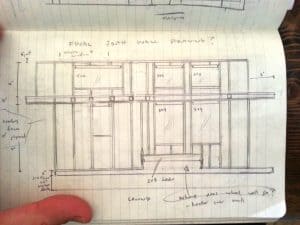

Framing Sketches

I've been slowly refining some floor and wall framing sketches over time as I gradually figure out how I will go about building things -- and my window sizes have shifted a bit for various reasons. This will be an ongoing process and will only be finalized once I have the windows ordered, and really only once I have them on hand to rough fit as I frame the walls. To be honest, I still have some major decisions to make such as: Can I get away with 24" OC 2x4 framing for the walls? Do I need to 16" OC for the subfloor, loft floor and roof rafters? Do I need to frame the subfloor with 2x6's to make more room for plumbing AND insulation? Can I use 4x4's for the loft? Or do I need 2x6's for the loft and roof, since technically a 2x4 can't span the 8 foot width? Every inch of headroom counts in a house this tiny, so even the 2 inches needed for 2x6 instead of 2x4 seems like a lot to give up.

Building Materials

It's been harder than I expected to generate a materials list and get materials packages/quotes put together by some local building supply companies. In addition to my own shortcomings in trying to put together a complete materials list (having never done this before and no real reference to start from), the spring building season has started so everyone is insanely busy meeting customer demand right now. I'm working on getting quotes for all the right materials in this coming week.

Though I will inevitably buy some materials from my nearest Big Box store (Menards is closest), I'm hoping to get reasonably priced quotes from other retailers, so I can support local business when possible. I'm currently talking with Green Building Supply here in Fairfield, Carrol Lumber in Ottumwa, Gilcrest/Jewett with locations throughout Iowa, and will be pricing items at the Ottumwa Mendars as well.

A big factor in overall cost of materials are my windows. With 10 windows in my design, it will be more costly for me than in most tiny house builds. Windows are a discussion all to themselves, so I've dedicated a whole post to factors pertaining to window decisions.

I'm really curious what factors you took into consideration when determining how to run your plumbing and propane. I've been rolling floorplan ideas around in my head for a while now but I would like to, as much as possible, simplify plumbing and heating. Things like putting the shower and kitchen close together and concentrating the plumbing into a single wet wall. What sorts of issues did you run into? Did you find any innovative ways to simplify, cut costs, increase durability, etc?

Grant - There was a lot of thought put into it to keep plumbing simple and all in one part of the house. I was also wanting to keep as much of the drain pipe in the insulated portion of the house to prevent freezing. My floorplan was designed specifically to keep all water basically in one corner of the house. If you look at this blog post, I've created a photo collage that shows my subfloor utilities. All my supply lines and drain lines run through the floor, so they can go directly where needed instead of circling around the walls of the house. Drain lines connect 3 different sources (kitchen sink on short end-wall, bathroom sink and washer/dryer on the long wall. The shower drain is separate as it needs it's own p-trap under the house. The shower drain is connected to the single exit for these other three, so there is only about a foot or two of exposed pipe outside.

It's not a single wet wall as you suggest. Most plumbing is in outer walls, except for the shower, which comes up into an interior wall, and I guess the washer/dryer hookup as well is on a separate interior wall. In a simpler house with just one sink and a shower, one wet wall would be perfect. But with 2 sinks and a washer, that wasn't possible for me.

The only issues I had weren't really issues, but just careful planning of the interior space ahead of time. Since all pipes run through the floor, then needed to come up at very precise points to hit interior walls or to line up with sinks that are just now being installed months later. With proper planning, it's worked out really well. Putting it all in the subfloor made for more work up-front, but made finishing up the rough plumbing in the interior walls super easy later one. I think it saved time over-all and certainly made things simpler. Same can be said for electrical. Only have wires running vertically up the walls since it was all planned out ahead of time and run through the floor to all the right places. This could be said to cut costs as well since you need less pipe/wire and probably fewer fittings too.

Hi Alek,

What was the final GVW of your trailer?

Thanks,

M.

I don't know the EXACT number, but it's very close to 10,000 lbs. It has t 6k axles (12k total) and the trailer weighs about 2k itself, so that leaves a 10k GVWR.